Introduction:

In optics, crystals are a fundamental component that plays a vital role in the performance of various devices such as lasers, optical sensors, and more. Among the different types of crystals used in optics, beta-barium borate (BBO) crystals are known for their excellent optical properties and high efficiency in nonlinear optics. However, to achieve the best performance from BBO crystals, their quality is a critical factor to consider.

This article aims to comprehensively understand BBO crystal quality, its significance in optics, and the factors that affect it. We will also cover assessing BBO crystal quality and ensure you obtain the best application crystals.

What is BBO Crystal Quality?

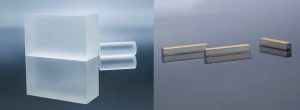

BBO crystal quality refers to the perfection of the crystal structure, homogeneity, and absence of defects or impurities. In other words, it measures how well the BBO crystal meets the required specifications for optical applications.

The Importance of BBO Crystal Quality in Optics

BBO crystals are widely used in optics due to their unique nonlinear optical properties, such as high conversion efficiency and wide transparency range. However, to take full advantage of these properties, high-quality BBO crystals are essential. Here are some reasons why:

Improved Optical Performance: High-quality BBO crystals ensure the best possible performance in various optical applications such as frequency doubling, sum-frequency mixing, optical parametric oscillation, and more. This is because the quality of the crystal affects its nonlinear coefficients, transparency, and overall efficiency.

Longer Lifespan: High-quality BBO crystals have longer lifespans and are more durable. They can withstand higher laser intensities and operate under extreme temperature conditions without damage.

Reduced Downtime and Maintenance Costs: Using high-quality BBO crystals can minimize device downtime and maintenance costs. Low-quality crystals tend to degrade faster and require frequent replacements, which can be expensive and time-consuming.

Factors Affecting BBO Crystal Quality

Several factors can affect the quality of BBO crystals, and it is crucial to understand these factors to obtain the best crystals for your applications. Here are some of the critical elements:

Growth Method

BBO crystals can be grown using various methods, including Czochralski, top-seeded solution growth, flux growth, and more. Each method has advantages and disadvantages regarding crystal quality, growth rate, and cost. For instance, the Czochralski method is known for producing high-quality BBO crystals, but it is expensive and time-consuming.

Raw Materials

The quality of raw materials used in BBO crystal growth also affects the crystal quality. The purity of the starting materials, such as barium oxide and boric acid, can influence the formation of defects and impurities in the crystal lattice.

Growth Conditions

The growth conditions, such as temperature, pressure, and atmosphere, can also influence the quality of BBO crystals. For example, higher temperatures and pressures can lead to faster crystal growth but may also result in the formation of defects and impurities. On the other hand, controlled growth conditions can ensure uniform crystal structure and higher crystal quality.

Post-Growth Treatment

Post-growth treatments, such as annealing, polishing, and coating, can further improve the quality of BBO crystals. Annealing at high temperatures can remove defects and improve crystal homogeneity, while polishing can enhance the crystal’s surface quality. Coating the crystal with anti-reflective materials can improve its optical performance.

How to Assess BBO Crystal Quality?

Assessing BBO crystal quality requires a thorough understanding of the crystal’s specifications and optical properties. Here are some key parameters to consider when determining BBO crystal quality:

Crystal Structure: The crystal structure determines the crystal’s optical properties and nonlinear coefficients. High-quality BBO crystals have uniform and well-defined crystal structures.

Absence of Defects: Defects such as cracks, dislocations, and inclusions can affect the crystal’s optical performance and lifespan. High-quality BBO crystals should be free of defects.

Transparency: BBO crystals should have high transparency over a wide wavelength range. The clarity can be affected by crystal defects and impurities.

Homogeneity: Uniformity in crystal composition and structure is crucial for achieving consistent optical performance in BBO crystals.

Ensuring High-Quality BBO Crystals

To ensure you obtain high-quality BBO crystals for your applications, here are some tips to follow:

Choosing a Trusted Supplier

They are selecting a reputable supplier with experience in BBO crystal growth and quality control. A reliable supplier can provide high-quality crystals that meet your specifications and requirements.

Requesting Quality Certifications

Ask your supplier to provide quality certifications, such as ISO 9001, to ensure that their production processes meet industry standards for quality management.

Conducting In-House Testing

Performing in-house testing, such as crystal structure analysis and optical measurements, can help verify the quality of the BBO crystals you receive from your supplier.

FAQs

What is the typical lifespan of BBO crystals?

The lifespan of BBO crystals can vary depending on their quality, usage, and environmental conditions. High-quality BBO crystals can last several years, while low-quality crystals may degrade in months.

Can BBO crystals be repaired or re-grown?

BBO crystals are difficult to repair once damaged. However, they can be re-grown using the same or a different growth method, depending on the extent of the damage.

How do BBO crystals compare to other nonlinear crystals in terms of quality?

BBO crystals are known for their high-quality and superior optical properties compared to other nonlinear crystals, such as lithium niobate and potassium titanyl phosphate.

Conclusions

In conclusion, BBO crystal quality is critical in achieving the best performance from optical devices such as lasers and sensors. Growth methods, raw materials, growth conditions, and post-growth treatment can significantly affect BBO crystal quality. By selecting a reputable supplier, requesting quality certifications, and conducting in-house testing, you can ensure that you obtain high-quality BBO crystals that meet your requirements and specifications.